As a dental professional, you know that your handpieces are the heartbeat of your practice. These precision instruments are essential for delivering exceptional patient care, but they demand meticulous maintenance to ensure their optimal performance and longevity. In this comprehensive guide, we will explore the best practices for dental handpiece care in 2024, empowering you to protect your investments and enhance your practice’s efficiency.

Choosing the Right Handpiece: Quality Matters

The longevity of your handpieces begins with selecting high-quality instruments from reputable brands. When evaluating potential handpieces, keep these crucial factors in mind:

- Reputation: Choose established brands known for their reliability and innovation, such as NSK, W&H, and KaVo.

- Performance: Assess the handpiece’s speed, torque, and noise level to ensure it meets your clinical requirements.

- Durability: Invest in handpieces made from premium materials like titanium and equipped with advanced bearing systems for enhanced durability.

While high-quality handpieces may come with a higher upfront cost, their superior performance and longevity make them a wise investment in the long run.

Mastering the Art of Handpiece Maintenance

Proper maintenance is essential for extending the life of your dental handpieces. By following these key steps, you can keep your instruments operating at peak performance:

1. Cleaning and Lubrication

- Surface Cleaning: After each use, flush the handpiece with water for at least 30 seconds to eliminate debris. Then, thoroughly clean the external surface.

- Lubrication: Regularly lubricate your handpieces according to the manufacturer’s guidelines. For air-driven handpieces, spray lubricant directly into the drive air hole until it expels from the head.

- Purging: Run the handpiece to distribute the lubricant and expel any excess. This step is vital to prevent oil buildup and ensure smooth operation.

2. Sterilization and Storage

- Sterilization: Always sterilize your handpieces between patients using an autoclave. Follow the manufacturer’s instructions for temperature and cycle duration.

- Drying: Allow the handpieces to cool and dry completely before storage to prevent moisture-related damage.

- Storage: Store your handpieces in a dry, dust-free environment away from direct sunlight and heat sources.

3. Regular Inspection and Maintenance

- Inspection: Periodically examine your handpieces for signs of wear, such as cracks, chips, or loose parts. Address any issues promptly to prevent further damage.

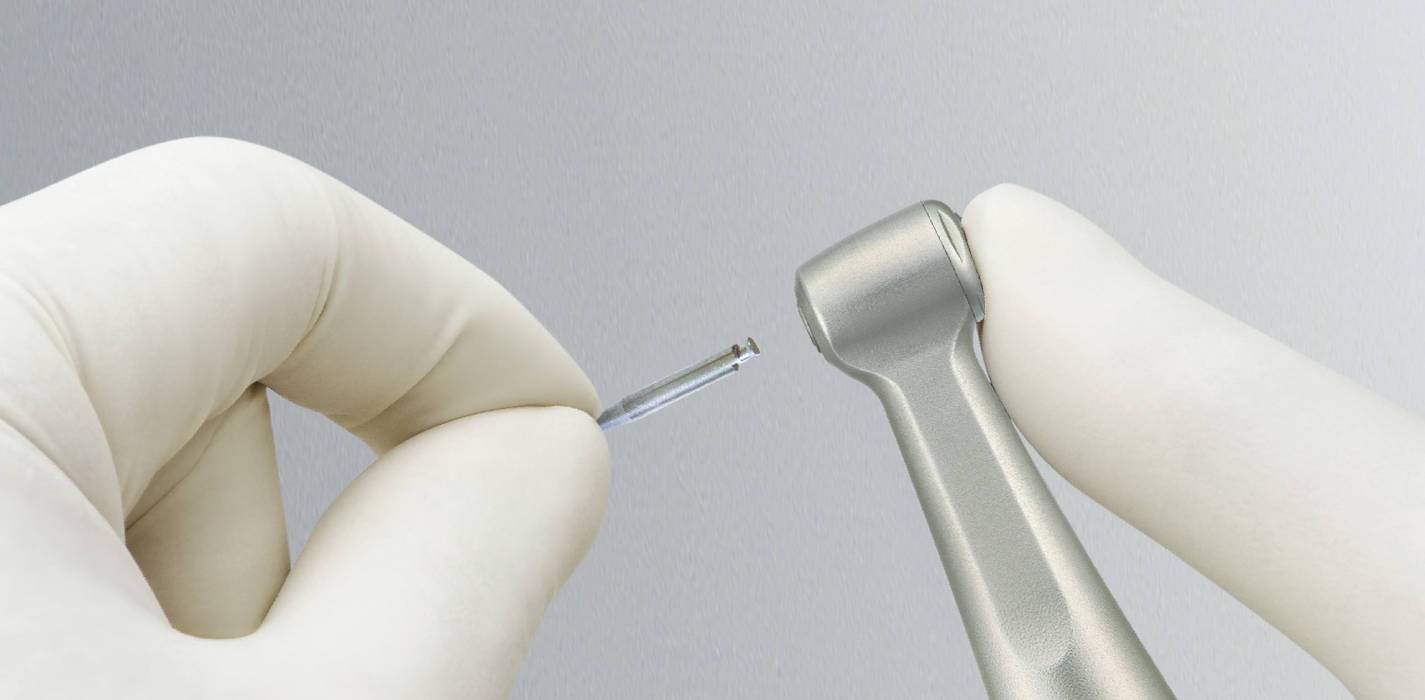

- Turbine Replacement: For air-driven handpieces, replace the turbine as needed to maintain optimal performance. Some models feature user-replaceable turbines for convenient in-office maintenance.

- Professional Servicing: Schedule regular professional maintenance with a trusted repair service to ensure your instruments receive expert care and remain in top condition.

Avoiding Common Handpiece Pitfalls

Even with diligent maintenance, certain mistakes can undermine the longevity of your dental handpieces. Avoid these common errors:

- Excessive Pressure: Avoid applying too much force when using your handpieces; excessive pressure can lead to premature wear and damage to bearings and gears.

- Improper Bur Usage: Always use ISO-compliant burs that are compatible with your handpiece. Using worn or damaged burs can cause issues like slippage or locking.

- Skipping the Cooldown: Never run a hot handpiece under cold water to speed up cooling; rapid temperature changes can damage internal components.

- Overuse: Limit each handpiece’s use to no more than three times per day to prevent overheating and premature wear.

By steering clear of these pitfalls and adhering to best maintenance practices, you can significantly extend the life of your dental instruments.

Elevating Your Practice with Optimal Handpiece Care

Implementing these dental handpiece care strategies will not only extend the life of your instruments but also minimize downtime, ultimately enhancing both efficiency and patient care in your practice. Remember that investing in quality handpieces and prioritizing their maintenance is an investment in the success of your dental practice.

As technology continues to evolve, staying informed about the latest innovations in dental handpieces and maintenance techniques is crucial. Attend continuing education courses, read industry publications, and engage with your dental community to remain at the forefront of handpiece care.

In this ever-changing landscape of dentistry, your commitment to exceptional handpiece maintenance will set your practice apart. By embracing both the art and science of dental handpiece care, you can deliver the highest standard of care to your patients for years to come. Watch as your practice thrives through dedicated attention to detail and quality instrument management.

Lubricate your handpieces before each sterilization cycle, or at least once per day. Always refer to the manufacturer’s guidelines for specific lubrication requirements.

No, it’s essential to use the lubricant recommended by the handpiece manufacturer. Using incompatible lubricants can lead to clogs, poor performance, and even damage to the handpiece.

With diligent maintenance and care, high-quality dental handpieces can last for several years. However, the lifespan of your handpieces will depend on factors such as usage frequency, sterilization practices, and the complexity of the procedures performed.

If you detect any unusual noises, vibrations, or performance issues, stop using the handpiece immediately. Contact the manufacturer or a trusted handpiece repair service for guidance on troubleshooting and repairs.

Electric handpieces generally require less maintenance than air-driven models, as they have fewer moving parts and do not require regular lubrication. However, it’s still crucial to follow the manufacturer’s guidelines for cleaning, sterilization, and professional servicing.